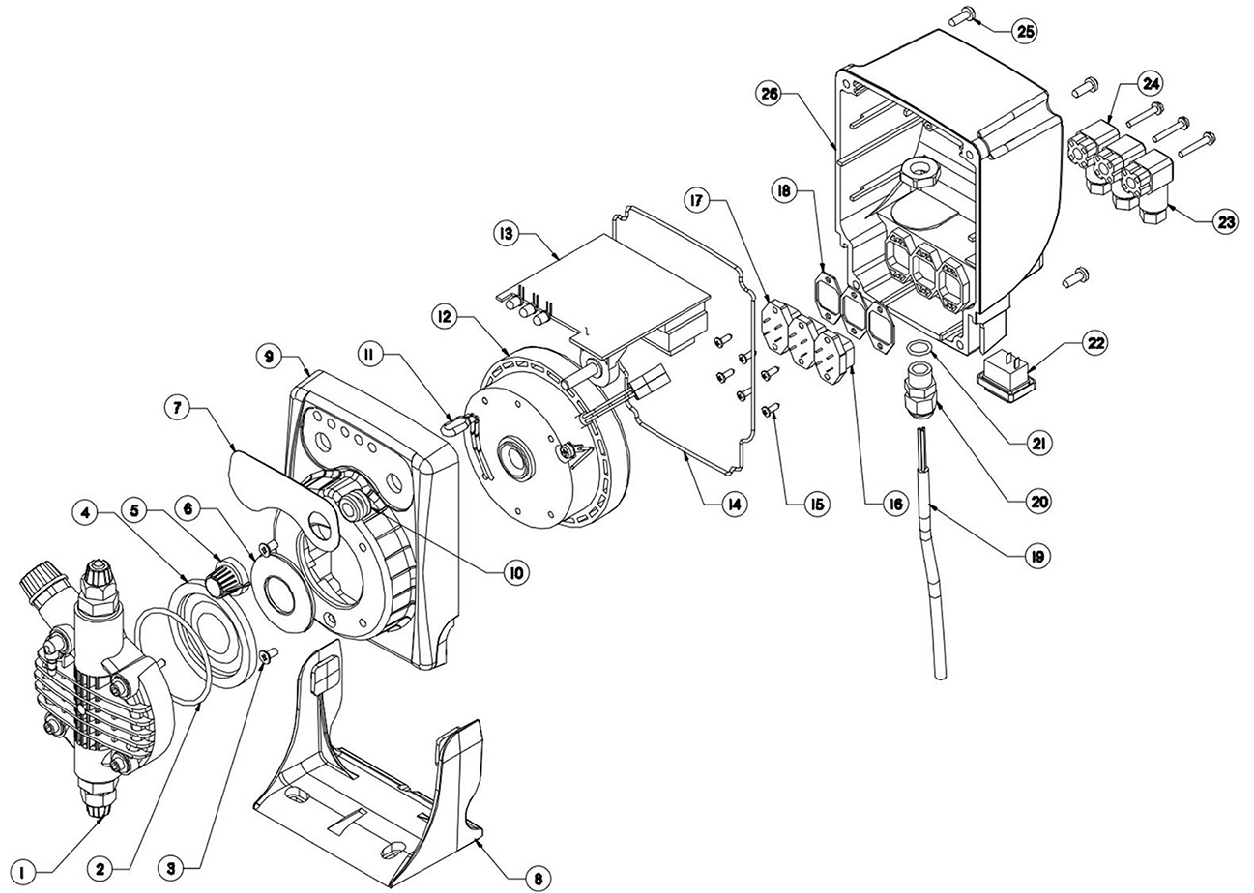

Dosing pump reagent PKX

Analog diaphragm pump PKX MA/A

Ручне управління 10-100%

Diaphragm pump PKX MA/AL

Ручне управління 10-100%

Вхід для датчика рівня

Dosing Pump PKX FT/A works from the flowmeter

Від витратоміра 1:1 або по таймеру

Dosing reagent pump PKX with manual control

- Productivity: up to 10 l/hour.

- Pressure: up to 7 bar.

Pump reagent pump PKX with polypropylene head - the simplest and cheapest in the product line of ETATRON D.S. All models have analog control. The plastic of the outer case is resistant to acid vapors. The air outlet valve is manual.

Class of protection of the case against water and dust IP65 (full protection against dust protection against a system of water). The universal bracket is included in the standard delivery set and allows to install the pump in horizontal or vertical position.

- PKX reagent dispenser pump with manual control

- Productivity: 1÷10 l/h

- Pressure: 1÷7 bar

- Suction height - 2 m

- Standard voltage - 230V 50Hz

- The pumps comply with CE standards

- Plastic case

- Manual air vent valve

- Ability to connect a level sensor (except for the PKX-MA / A model)

- Installation options: wall / horizontal mounting

- Protection class: IP65

- Compact dimensions: 158x106x144 mm

PERFORMANCE SCHEDULES PKX

TECHNICAL INFORMATION

| Type pump | Max. flow | Price without VAT, (€) | ||||||

| l/hour | bar | MA/A | MA/AL | FT/A | MA/A 12Vdc, 24Vdc/Vac |

MA/A 12Vdc SOL |

120V | |

| 0105 | 1 | 5 | 193 | 212 | 230 | 212 (24Vac) | 213 | +10% |

| 0206 | 2 | 6 | 189 | 207 | 208 | 207 (24Vac) | - | +10% |

| 0303 | 3 | 3 | - | - | - | - | 207 | +10% |

| 0505 | 5 | 5 | 189 | 207 | 208 | 207 (12Vdc) | - | +10% |

| 0507 | 5 | 7 | 211 | 230 | - | - | - | +10% |

| 0702 |

7 | 2 | 189 | 207 | 208 | - | - | +10% |

| 10 | 1 | |||||||

Different variants of transformation of PKX dosing pumps by means of a universal arm

Versions of PKX series pumps

MA/A is the simplest option with manual control. The pump dispenses the reagent in two modes: on or off. There are 2 indicators on the control panel: mains power and on/off. Manual productivity control - by means of the potentiometer handle. Does not support the level sensor.

FT/A - this type of dispenser is controlled by a pulse flow meter. The pump can be operated in two modes:

- a) Proportional dosing 1:1 - for each pulse of the flowmeter one working stroke of the dosing pump is necessary.

- b) Dosing in a time interval - for each pulse of the flowmeter the pump is switched on for a time from 0 to 60 seconds (time is adjusted).

Supports a level sensor and has 3 indicators on the control panel similar to the MA/AL option.

Operating conditions

- The ambient temperature should be between 0 and +40°C.

- Relative humidity is not more than 80% if the ambient temperature is up to +31°C. At +40°C relative humidity no more than 50%.

- Power supply single-phase 200-260 volts, except for the PKX 03-03 model, in which the power supply is 12 volts.

- The height of the pump during operation must not exceed 2000 meters above sea level.

Construction materials

:

- The pump head (flow part) is made of polypropylene (PP).

- Teflon working membrane (PTFE).

- Nipple of a head from polypropylene.

- Sticky Viton valves.

- O-ring seals made of viton.

- Intake valve - made of polypropylene / ceramic.

- Output valve - made of polypropylene / ceramic.

- Intake (inciting) hose - made of PVC.

- Drain hose - made of polyethylene.

Delivery KIT

Each PKX pump is supplied as standard:

- Dosing pump (1 pcs).

- Universal mounting bracket.

- Flexible intake hose made of PVC (4 meters).

- Reset hose (2 meters).

- Intake valve (1 pcs).

- The final valve (1 pcs).

- Passport-instruction (1 pcs).