Dosing pumps DLX

Solenoid analog pump DLX MA/AD

Ручне управління 10-100%, 2-20%

Дозуючий насос DLX MA/MB

Ручне управління 0-100%

з кроком 1%

Багатофункціональний цифровий насос DLX MF/M

Пропорційний від імпульсного витратоміра, 4-20 mA.

Насос дозатор DLX PH-RX/MBB

З вбудованим контролером рН / RedOx (на вибір)

Дозуючий насос DLX PH-RX-CL/M

З вбудованим контролером рН / RedOx / Cl (на вибір)

Насос дозуючий DLX з електроспоживанням 12V / 24V

Насоси працюють від 12В і 24В,

від сонячних батарей

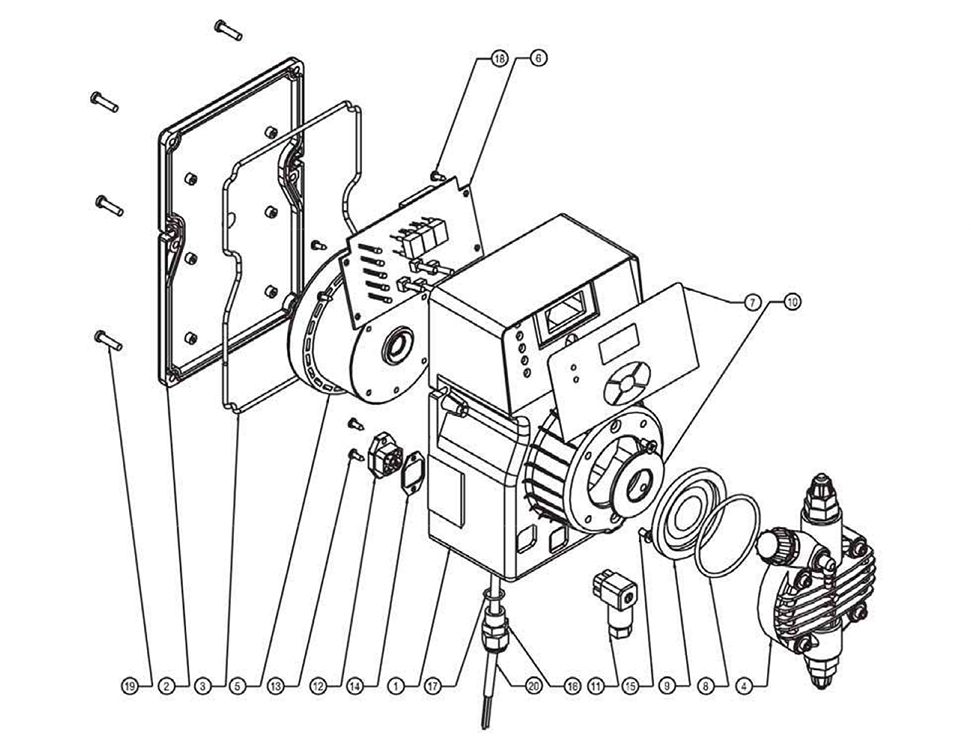

Solenoid diaphragm dosing pumps DLX

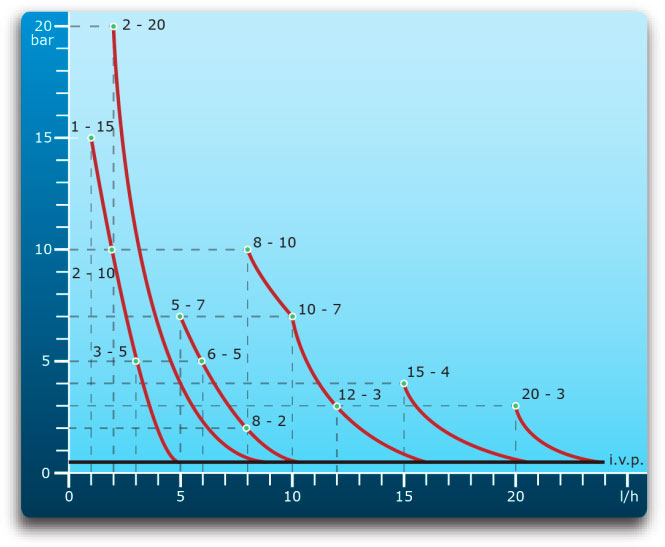

- Productivity: from 1÷20 l/hour.

- Pressure: up to 20 bar.

DLX solenoid diaphragm dosing pumps are the most versatile series with a PVDF fluoroplastic head. High chemical resistance of pump materials allows to use for dosing practically any reagents. DLX solenoid pumps can be made with both analog and microprocessor control. Pump housings made of plastic, protected from acid vapors. The control panel is protected from ultraviolet radiation by a special film. Protection against dust and moisture IP 65. Standard height of the self-suction for all models is 2 meters.

DLX dosing pumps are installed vertically, wall mounting. A special version of the DLXB is equipped with a bracket for mounting on a horizontal surface. DLXB dosing pumps are 20 euros more expensive than a DLX pump.

Performance adjustment for the DLX series is performed by changing the number of pulses per minute. However, for the DLXB variant, an additional R/C cover is provided, which allows you to change the stroke length of the piston for more accurate dosing at minimal cost. The cost of such a cover is 60 euros

Technical characteristics:

- Dosing solenoid pumps with analog and microprocessor control;

- Constant and proportional dosing;

- Dosing pumps comply with EU standards

- Advanced digital technology, best price / quality ratio;

- Modern technology of dosing pumps with built-in controllers of pH, Rx (ORP), CL, CD - in compact execution.

- Anti-acid plastic case, the control panel is protected by a film from UV radiation;

- Productivity: 1÷20 l/h;

- Pressure: 1÷20 bar;

- Suction height: 2 m;

- Wall execution;

- Protection class: IP65;

- Dimensions: 190x120x150 mm

EXTERNAL DIMENSIONS

PERFORMANCE SCHEDULES

TECHNICAL CHARACTERISTICS

| Type | Cost | Pressure | Pump head type |

Price without VAT, (€) |

|||||

| l/hour | bar | MA/AD | MA/MB | VFT/MBB | MF/M | pH-Rx-Cl/M | pH-Rx/MBB | ||

| 0115 | 1 | 15 | E | 233 | 259 | 356 | 383 | 502 | 471 |

| 2 | 10 | ||||||||

| 3 | 5 | ||||||||

| 0220 | 2 | 20 | C | 347 | 416 | 438 | 466 | 592 | 560 |

| 0507 | 5 | 7 | E | 238 | 269 | 356 | 383 | 502 | 471 |

| 6 | 5 | ||||||||

| 8 | 2 | ||||||||

| 0810 | 8 | 10 | E | 295 | 348 | 386 | 413 | 540 | 508 |

| 10 | 7 | ||||||||

| 12 | 3 | ||||||||

| 1504 | 15 | 4 | E | 319 | 389 | 412 | 441 | 564 | 533 |

| 2003 | 20 | 3 | B | 347 | 416 | 438 | 466 | 592 | 560 |

- 120V - +10%

- R/C - +66 euro

The principle of operation of the dosing pump DLX

The principle of operation of the dosing pump is as follows: on the piston (plunger), which is actuated under the influence of a constant electromagnetic field of the solenoid, a Teflon membrane is attached. When the piston moves forward (under the influence of the electromagnetic field) there is pressure on the pump head, while the liquid is released through the discharge valve. After the end of the electromagnetic field, the piston returns to its original position by means of a spring, while there is an automatic intake of liquid through the intake valve.

The principle of operation is very simple, and the pump does not require lubrication, which reduces the maintenance process to almost zero.

The materials used to make the pumps make it possible to dispense aggressive liquids.

Different versions of DLX series pumps

The DLX dosing pump line consists of 8 different versions.

MA/AD is the simplest pump with manual control. The only analog pump in the DLX line. Has a double dosage scale in the range of 10-100% and 2-20% (for more accurate dosing of small volumes). The only pump in the DLX line that does not support the level sensor.

MA/MB - dosing pump with microprocessor control. Instead of the rotating handle of the potentiometer productivity is set on the digital display with a step in 1%.

CC/M - pump proportional dosing from external 4-20 mA signals. Dosing in manual mode is also possible (similar to the MA / AD variant). Supports reversible dosing.

VFT/MBB - proportional dosing pump from external pulse flow meter. For each pulse, the pump gives a certain portion of the reagent (the portion is set in the modes 1xN, 1: N, 1xN (M - with a parameter in memory), where N is the number of received pulses). Can also work in manual dosing mode.

MF/M is the most advanced version of the proportional dosing pump, which supports both pulse flow meter and 4-20 mA signals. The only pump in the DLX line that has a two-line backlit LCD display (all other microprocessor pumps have a single-line backlit display). Also has a timer, buzzer, clock, relay alarm output. In addition to the level sensor, the pump supports the flow sensor (not included).

PH-RX/MBB - proportional dosing pump with integrated pH / RedOx controller. The user determines which parameter the pump controls. pH is measured in the range from 0 to 14, and RedOx (redox potential) from -1000 to +1400 mV (millivolts). The pump operates in a constant or proportional mode. Power-on delay function. In addition to the level sensor, the pump supports the flow sensor (not included).

PH-RX-CL/M - version similar to the previous one, but in addition to the pH / RedOx controller, a CL chlorine controller (measuring range 0-20 ppm or mg / l) is also added. Output 4-20 mA. Alarm relay output. Temperature compensation in automatic mode (when installing the appropriate PT100 sensor). In addition to the level sensor, the pump supports the flow sensor (not included).

CD/M - proportional dosing pump with CD (conductivity) controller. Electrical conductivity is measured in the range from 0 to 1000 or from 0 to 10,000 μS (microximens or μS). Output 4-20 mA.

Appearance of control panels of various versions of DLX pumps

Operating conditions

-

The ambient temperature should be between 0 and +40°C.

-

Relative humidity is not more than 80% if the ambient temperature is up to +31°C. At +40°C relative humidity no more than 50%.

-

Power supply single-phase 220 volts (permissible deviation 210-250 volts). DLX pumps with a low voltage supply of 12 volts can be manufactured on request.

-

The height of the pump during operation must not exceed 2000 meters above sea level.

Construction materials

DLX series pumps are made of the following materials:

- Pump head - PVDF (except model 0220 made of PVC and model 2003 made of polypropylene).

- Teflon working membrane (PTFE).

- Ceramic ball valves, except models 0220 and 2003, which have Viton lip valves (FPM).

- Elastic Viton gaskets (FPM).

- Polypropylene / ceramic intake valve.

- Polypropylene / ceramic injection valve.

- Suction hose (drain) - made of PVC (size 4x6, transparent color).

- Injection hose made of PE (size 4x6, matte).

Delivery KIT

Each DLX pump comes standard with:

- Dosing pump (1 piece).

- Flexible intake hose made of PVC (4 meters).

- Reset hose (2 meters).

- Intake valve (1 piece).

- Injector valve (1 piece).

- Passport-instruction (1 piece)